Our approach

Health, safety and the environment (HS&E)

The Group believes that good HS&E performance is synonymous with good business performance. Our stated vision is to be recognised widely for the excellence of our HS&E performance and we aim to have world-class levels of performance across Rolls-Royce sites. These aspirations are supported by a comprehensive strategy and initiatives endorsed by the Group Executive.

HS&E management

The Group’s arrangements for HS&E governance and management systems implementation are detailed in our Policy & Management Arrangements booklet available on www.rolls-royce.com. We believe that all cases of work related ill health, injuries and environmental incidents are avoidable.

A full review of the HS&E organisation has been completed during 2008. Improvements aim to increase both the efficiency and effectiveness of HS&E and include the appointment of regional HS&E directors, the development of shared services and the recruitment of high calibre HS&E professionals.

All the Group’s businesses have third-party certification to the environmental management system standard ISO 14001, and our comprehensive Corporate HS&E audit programme assesses the implementation of the HS&E management system across all businesses on a rolling audit basis. This year, audits took place in the UK, US, Canada and Brazil across all businesses. In addition, an independent audit of compliance with COSHH (Control of Substances Hazardous to Health) took place at several UK facilities.

The Group has recently committed to a programme of third-party certification to OHSAS 18001, the standard for Occupational Health and Safety management systems, across all businesses by 2012. This will provide independent assessment across all of the elements of our HS&E management systems. Both the ISO14001 and the OHSAS 18001 international standards are supported within the Group by a comprehensive range of global standards and include pertinent areas such as risk management.

We operate three sites in the UK which together manufacture, test and support nuclear reactor cores for Royal Navy submarines. The Company Nuclear Propulsion Assurance Committee monitors the performance of these sites regularly to ensure that the highest standards of health and safety are maintained and that processes are robust and fit for purpose.

The Group’s contribution to developing best practice through third-party collaboration continues to grow. We are taking a leading industry role in REACH, the latest EU chemicals regulation, and continue to work with other companies, trade bodies, sectors and regulators to prepare for implementation.

Efforts have been focused on raising awareness within our supply chain, such that appropriate arrangements for compliance and business continuity, including the targeting of any futures 'substances of very high concern’, are introduced well ahead of deadlines. Within the aviation sector we have helped the development and launch of international standards for the phased declaration of substances in ‘articles’ supplied to us to facilitate future REACH compliance and, where required, industry-wide substitution programmes.

We continue to participate and meet our ongoing commitments under various climate change agreements such as the UK Emissions Trading Scheme, the EU Emissions Trading Scheme and the US Chicago Climate Exchange greenhouse gas emissions trading scheme.

Operational performance

To achieve our vision we continue to implement robust processes in order to deliver against a number of key objectives and targets by the end of 2009. These are detailed in our latest progress report ‘Responsible Operations’, which is available on the Group’s website at www.rolls-royce.com. We are already making good progress against these targets across all of our operations and have plans in place to sustain this improving performance.

Our data collection and reporting is subject to independent assurance and recommendations for improvement by Deloitte LLP.

In summary, our 2007-2009 objectives and targets are to:

Target: Reduce the incident rate of occupational diseases and other work-related ill health by ten per cent by the end of 2009

Target: Achieve a 15 per cent reduction in the lost-time injury rate (over one day) by the end of 2009

Target 1: Achieve a ten per cent reduction in energy consumed (normalised by financial revenues) by the end of 2009

Target 2: Achieve a ten per cent reduction in solid waste (normalised by financial revenues) by the end of 2009

Target 3: Achieve a 58 per cent recycle rate of solid waste by the end of 2009.

There were no fatalities in the Group during 2008. It is with regret that we report the death of a contractor while working for a construction company on a new facility at our energy business in Mount Vernon, Ohio. The UK Health & Safety Executive has prosecuted the Group for two incidents during the year and preventative actions have already been taken to avoid reoccurrence of similar incidents in the future. One incident related to the disabling of an interlock device by a machine operator in our Sunderland (UK) manufacturing facility. The second involved the exposure of agency workers to sand during the decommissioning of a foundry in Derby (UK). The sand contained an additive which is known to be an irritant.

Product environmental performance

Rolls-Royce has a heritage of environmental innovation which means the Group is well placed to help society address the problems of climate change and energy security. We are determined to play a significant role in overcoming these challenges.

The priority we attach to the environment is reflected in the profile of our research and development expenditure, investing more than £800 million every year of which at least two-thirds is directed at reducing the environmental impact of our products and operations.

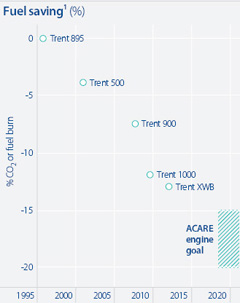

Thanks to our technological expertise, we have significantly reduced the fuel consumption of our civil engines since the first jet airliners entered into service along with substantial reductions in smoke and noise. For example, the Trent 1000 engine is 25 per cent more efficient than the first RB211 engine.

The Trent 900 and 1000 engines, for the Airbus A380 and Boeing 787 respectively, and in future the Trent XWB for the Airbus A350 XWB, help us make progress towards meeting our ACARE (Advisory Council for Aeronautics Research in Europe) goal of a 15-20 per cent reduction in engine fuel burn by 2020 compared to 2000 levels.

We are taking a leading role in research, including the Environmentally Friendly Engine (EFE), a joint Government, industry and university programme, aimed at improving the environmental performance of an aero engine. In 2008, the European Commission approved the launch of the Clean Sky, Joint Technology Initiative, in which Rolls-Royce will lead a €400 million engine research programme over the next seven years.

Environmental performance is fundamental across all of our businesses. For example, in the marine sector, our market leading Azipull thrusters use 16 per cent less fuel than conventional thrusters. This means that ships use less energy resulting in lower emissions.

The Group is investing in other renewable energy sources such as tidal power, working in partnership with the UK Energy Technologies Institute. In addition, we are working with fuel companies to ensure that future bio fuels meet our requirements, with the important caveats that they are sustainable, do not compete with the growth of food crops and are used in the most effective way to maximise the reduction in greenhouse gas emissions.

Nuclear power will represent an important component of future low-carbon electricity generation, sitting alongside renewables and other measures. In 2008, Rolls-Royce established a new civil nuclear business unit in response to the opportunities presented by future expansion of civil nuclear power.

The Group believes that technology must be applied on an industrial scale, through companies such as Rolls-Royce with its global reach, to achieve significant reductions in emissions to address climate change. The Group’s report on environmental performance, ‘Powering a better world’, is available on the Group’s website at www.rolls-royce.com.

1 SFC: fuel consumption normalised for engine power ACARE: Advisory Council for Aeronautics Research in Europe